CO2 Storage: To U or not to U?

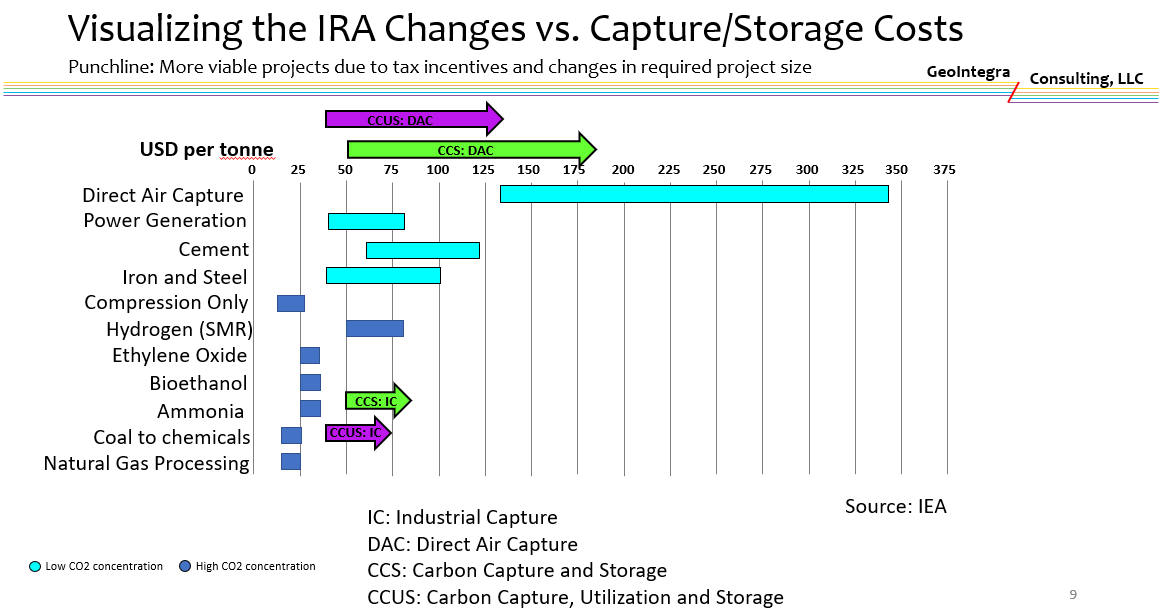

With the passing of the Inflation Reduction Act in 2022, the energy transition industry has seen a flurry of activity, particularly around the topic of subsurface carbon storage. This is a technology that has been around for decades, and is seen by proponents as a key component of keeping temperature below the 1.5°C mark, as recommended by the IPCC (International Panel on Climate Change). Detractors describe it as a "failed technology" that enables oil and gas companies to maintain status quo. But what really is CO2 sequestration? How does it work? What are its pros and cons? Let's dig into the two different categories of subsurface storage sequestration: CCS (Carbon Capture and Storage) and CCUS (Carbon Capture, Utilization and Storage).

CCUS: The basics

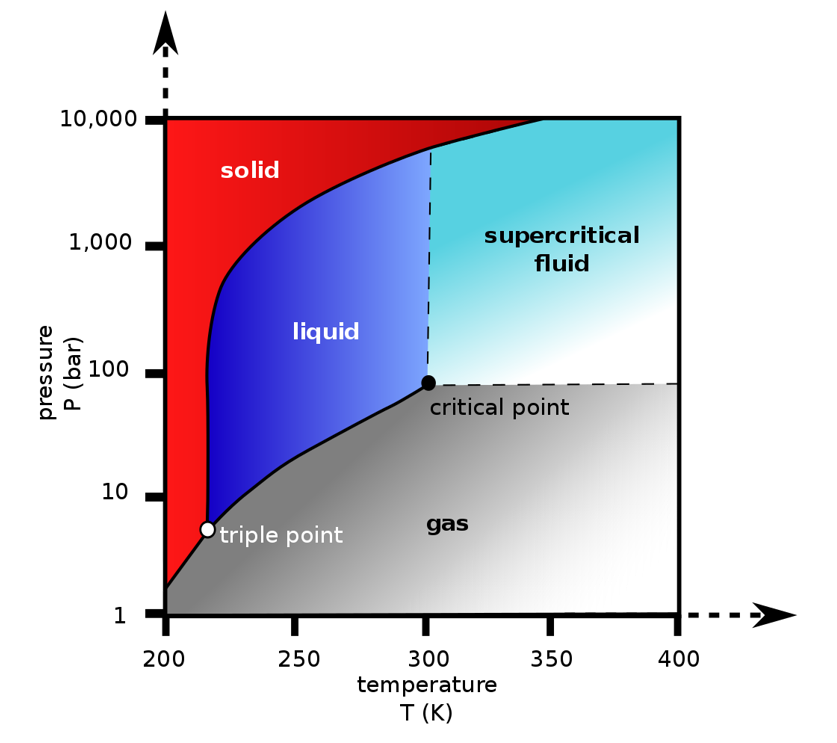

We begin with the more mature technology: CCUS. Starting in the late 1970s, oil and gas companies began to experiment with CO2 injection into oil and gas reservoirs as a method to produce more hydrocarbons. These Enhanced Ultimate Recovery (EUR) programs benefitted from CO2 injection because, when injected as the right temperatures and pressures, the compressed CO2 becomes supercritical. Supercritical CO2 has a density similar to a fluid like water or oil, but its physical properties are more like a gas. The former allows for higher amounts of CO2 to remain underground during and after CO2 injection, and the latter creates and efficient sweep mechanism that squeezes out oil or gas that would have been otherwise impossible to recover.

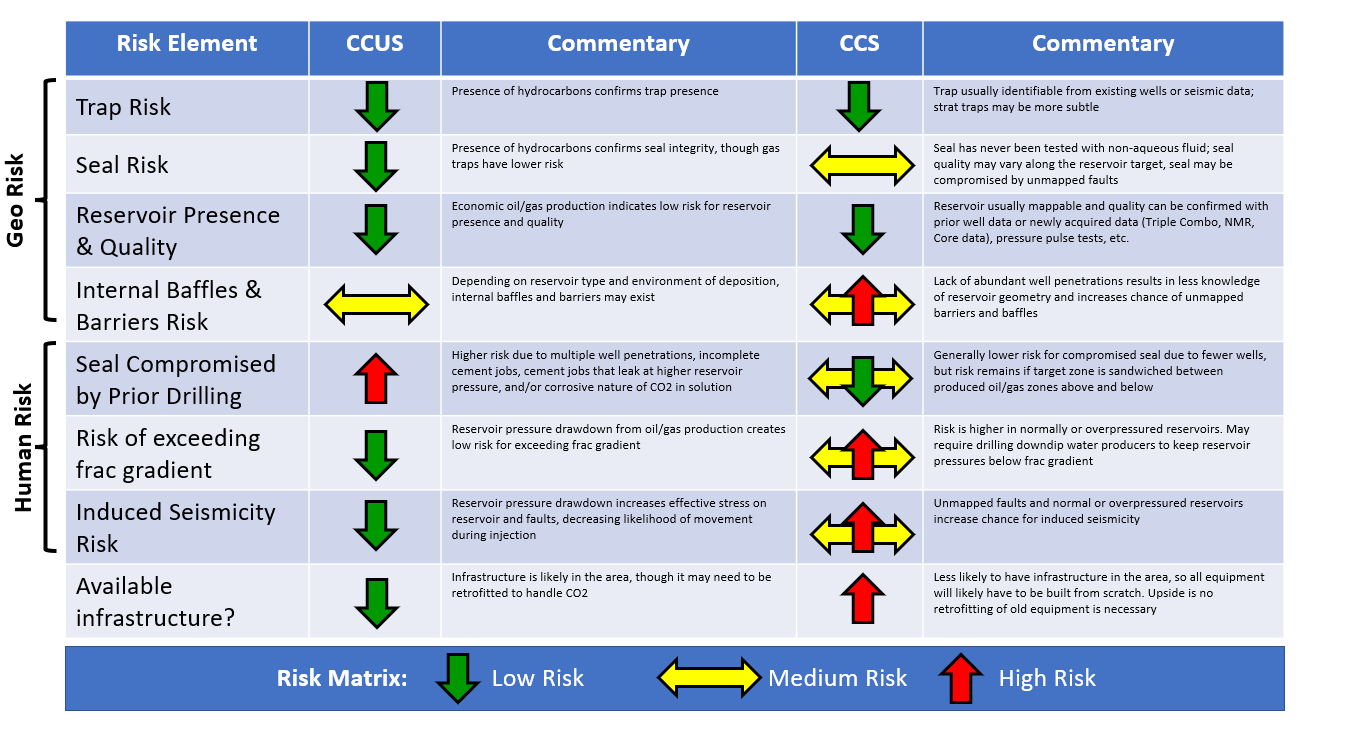

What makes CCUS an attractive option for permanent CO2 storage? There are many financial benefits (including producing more oil), but we will focus on the subsurface risks imparted by the geologic setting, or new risks created by human activity, like drilling holes into the reservoir, as summarized in the table below. In general, CCUS targets represent a low risk injection target. CCUS benefits from an abundance of data, including well data such as well logs and production metrics, and geophysical data like seismic imaging. The target reservoir is very likely to be high quality...after all, if the formation could produce oil and gas at economic rates, it would likely allow for high injection rates as well, right? Because these formations have produced oil and/or gas, the formation pressures are much lower, allowing for higher volumes of CO2 to be stored in a given unit of rock volume, and the chance of fracturing the seals that surround the target reservoir or inducing fault movement in the area is much lower.

The key risk that exists for CCUS is that the seal rocks that surround the reservoir may have been compromised by the numerous wells required to produce the oil and gas. Many wells were designed for oil and gas production, not CO2 sequestration, and may represent a leak point for CO2. When CO2 mixes with water, it forms carbonic acid that can, over time, etch away at older steel casing or cement used to secure the casing. Poor cement jobs can also create channels behind the casing that fluids can follow up to shallower intervals, which is clearly not an acceptable outcome. All CCUS projects must be vetted by trained geologists that can screen for these kinds of risks, both human and geologic.

CCS: The basics

CCS is most commonly defined as the capture of CO2 from industrial sources and storage in the subsurface over geologic (very long!) time frames. Typical subsurface targets are saline reservoirs; these are bodies of porous rock that permit sufficiently high rates to permanently store large volumes of CO2. Saline aquifers are also targeted for CCS specifically because the salty brines within cannot be used for any other purpose at the surface, and are usually deeply buried and well separated from freshwater aquifers above.

What advantages belong to CCS? There are several technical factors that are typically low risk for CCS. Since few, if any, wells have previously penetrated the target formation, there is a reduced risk of the seal rocks being compromised by prior human activity. The traps are usually readily discerned using available subsurface data like wells and seismic volumes, and pilot wells can be used to confirm the quality of the reservoir rock before any other drilling or CO2 injection begins. Since these regions have very few older boreholes, any drilling and completions practices can be done using specialized casing and cement that ensures a low chance of seal failure around these new boreholes. Furthermore, much of the United States that was unsuitable for oil and gas exploration are well suited for CCS, opening up reservoir targets that are closer to industrial point sources like ethanol plants and coal or natural gas-fired power plants.

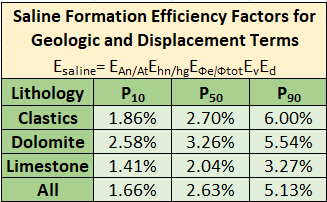

There are some disadvantages of CCS, however. Since the seal rocks have never held oil and gas, we do know that the seal is of sufficient quality along the entirety of the trap, thus the risk for seal rock integrity can be higher. Reservoir quality can be confirmed using logs and core data, but internal baffles and barriers may exist outside of those data points that may impair injection rates and storage volumes. Because saline aquifers have original formation pressures, operators may not be able inject as much CO2 into the formation due to risk of fracking the seal rock or induced seismicity along fault planes in the area. Because water is highly incompressible, these saline aquifers typically have low CO2 storage efficiencies (typically around 2% of the available pore volume) compared with CCUS (20-60% of the total pore volume.)

Conclusions

Each CCS and CCUS project has a unique human and geologic risk profile that must be carefully evaluated before, during and after CO2 injection occurs. Even though some elements may have higher risk, they can be mitigated by performing a detailed subsurface study that integrates all available data. In doing so, both CO2 injection targets can be considered in the future, and can still be an key resource in our global effort to combat the impacts of climate change. Contact us today to discuss how we can help you better understand your subsurface situation!

By

By